Products

Industries We Serve

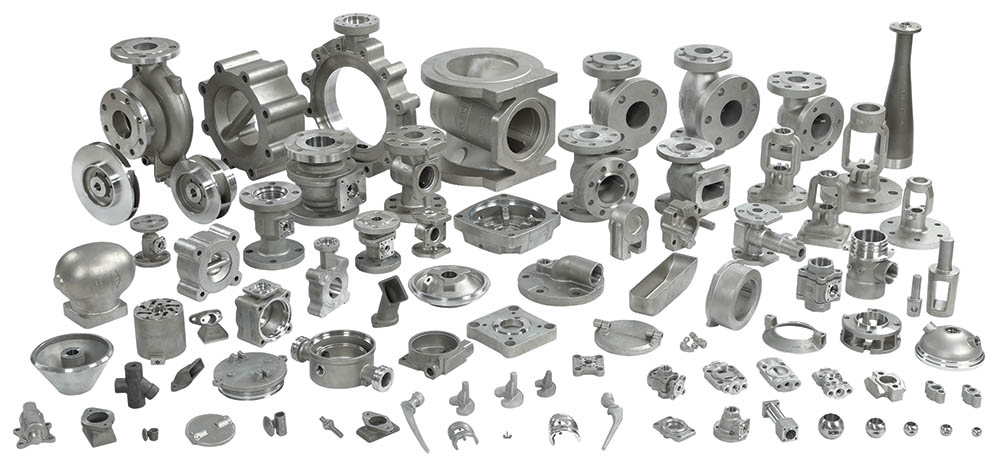

Pumps & Valves Castings

Earth Moving Castings

Gas, Oil & Instrumentation Casting

General Engineering Casting

Sand Casting

At we manufacture Sand casting single piece weight of 3650 Kg which is approximately 36” class 150 Ball Valve Body. Our melting shop is equipped with two medium frequency Induction Furnaces of 450 KW & 1000 KW, with varying crucible of 400 Kg, 900 Kg,1200 Kg,1500 Kg & 3000 Kg. To support the need of small Qty requirement in high alloys or in Nickel alloys we have specifically installed a small crucible of 100 Kg.

Two Heat treatment furnace we have is Natural Gas fired, Batch type, Size: W: 1500MM X D: 2000MM X H: 1200MM, having loading capacity of 3000 Kg. It is monitored by UNISCAN software to know the real trends of temperature in different zones. The heat treatment furnace is surveyed as per ASTM A991, API-6A Annexure M. Our moulding shop is equipped with Semi mechanized loop line suitable for small weight - high qty & hand moulding for bigger sizes. We have state of art machining facility equipped with CNC, VMC & HMC. ASTIM A991,API-6A, Annexuve-M

DIN 1.4107, 1.4408, 1.4306, 1.4308, 1.4462, 1.4837, 2.4686, 1.4581, 1.4309, 1.4552, 1.4409, 1.4584, 1.4828, 1.4825, 1.4313, 1.4470, 1.4435, 1.4517, 1.7357, 1.4512, 1.4511, 1.4086.

WCB, WC6, WC9, CA15, CA40, HE, HH, CF8, CF8M, CF3, CF3M, CN7M, CD4MCu, CG8M, CK20, Ch20, CK3MCuN, M35-1, M25-S, CW12MW, N-12MV, N7M, CY-40, CW-6M, CW-6MC, Cu5MCuC, Cz100, 50Ni-50Cr-Cb, CB7Cu-1 (17-4PH), CD3MN (Duplex 4A), CE3MN (Duplex 5A), CD3MWCuN (Duplex 6A), CD4MCuN, HK, CA6NM, M-30C, Cobalt alloys 6 & 12, CW-2M. CX-2MW, CD3MCuN, CD3MWCuN, B148 C95800 (AB2) and SB-62 (UNS C-83600) Bronze, F75 CoCr Alloy (for orthopaedic implants through vacuum melting), Inconel 713C (proprietary alloys through vacuum melting for turbine wheels)

Through AIR & VACUUM melt Investment casting & AIR melt Sand casting SOME OF ASTM, DIN, BS & proprietary alloys poured are:

Investment Casting

At , we manufacture Investment Castings weight of single piece casting 40 Kg. ideally (having facility & technical capabilities to cast up to 120 Kg). We are equipped with 47 nos. of high tech wax injection presses, state of art shelling area having environment control with respect to temperature, humidity and 3 nos. of auto clave for de-waxing.

Our Melting and Heat treatment shops are equipped with: Four 250 kW and One 550 kW medium frequency induction furnace with varying crucible of 50 kg (1 nos), 150 kg (2 nos), 250 kg (9 nos.), 750 kgs (1 nos) and one medium frequency Vacuum melting for type VIM-IC 1 E-BP, Equiaxed Bottom Pour, designed for turbine wheels and orthopaedic implants. Our Heat treatment shop is equipped with two electrically heated, Batch type, size: W 1500mm x D 1200mm x H 750mm, one PNG fired batch type (maximum temperature attained is 1250 Degree Centigrade) having loading capacity of 1000 kgs and two Electrically heated, Batch type having loading capacity of 250 kgs. All Heat treatment furnaces are monitored by SCADA base software for real trends of different zone for individual furnace.

Entire operations are running with ORACLE base customized foundry software, which is unique for our process. 90% of production capacity is utilizing for manufacturing of Valves & Pumps castings viz 3 pc, 2 pc & Single pc ball valve, Top entry ball valve, Plug, Diaphragm, Swing check, Safety relief, Dual plate check valve, Trunnion mounted ball valve (TMBV), Soft seated, Knife gate, Pneumatic, Steam trap, Butterfly, Non Return, Gate, Globe valve, Pressure transmitter, Transducer, Actuator, Slurry pumps, Dairy pumps, Chemical handling pump, Submersible pumps, Screw pump, Diaphragm pump & castings for sea water handling and used in RO process etc. Whereas 10% of productions is utilizing for general engineering, orthopaedic implants and turbine wheels.

Composition we cast are Ferrous alloys, low & high alloys, steel, stainless steel including duplex steel, all air melt Nickel, Nickel alloys and selected Non Ferrous alloys and selected Nickel base vacuum melting alloys.