Infrastructure

At Gujarat Intrux Limited we manufacture Steel and Alloy steel Sand casting single piece weight of from few Kgs. to 3650kgs.

We are Equipped with

-

Semi automatic moulding loop line.

-

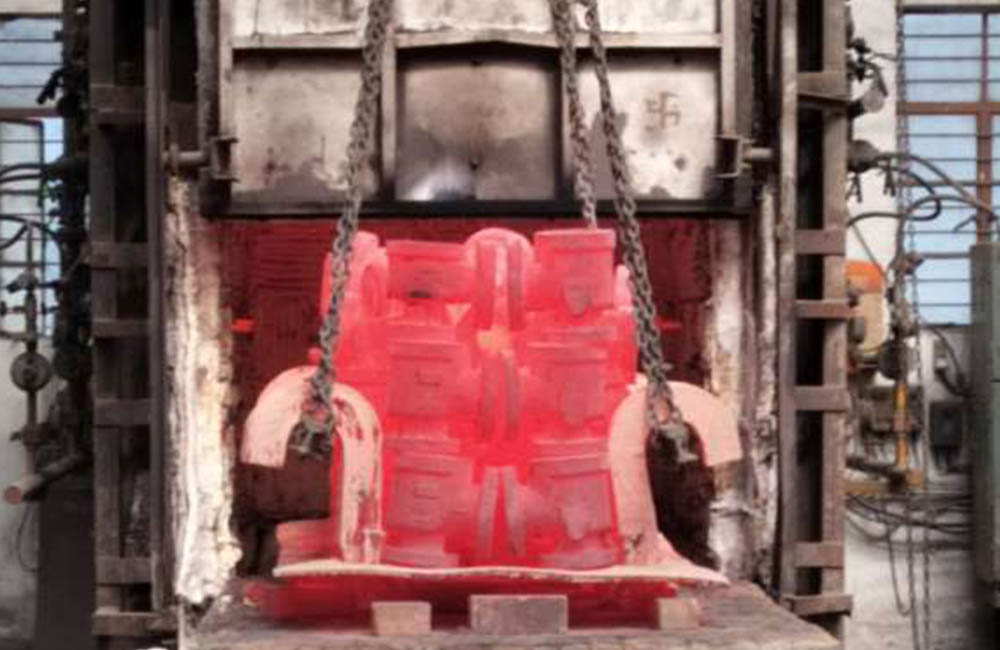

Melting shop is equipped with two medium frequency Induction furnaces of 450 & 1000 KW, with varying crucibles of 100kg, 400kg, 900kg, 1200kg.,1500kg and 3000kg. At Intrux we have bottom pouring as well lip pouring ladle which accommodate castings size of few kgs to 3650kgs.

-

Shakeout unit: for cleaning and removal of sand from the poured mould.

-

Grit blasting and shot blasting.

-

Two Heattreatment fuenace in Heat treatment shop equipped with Natural Gas fired furnaces,maximum temperature we are attending is 1150 Deg Cent. Heat treatment furnaces are monitored by UNISCAN software to know real trends of different zone for individual furnace.

-

Spectrophotometers - SPECTROMAXx direct reading optical emission spectrometer - Spectro Germany (Two base: Fe-Ni, 24 elements)

-

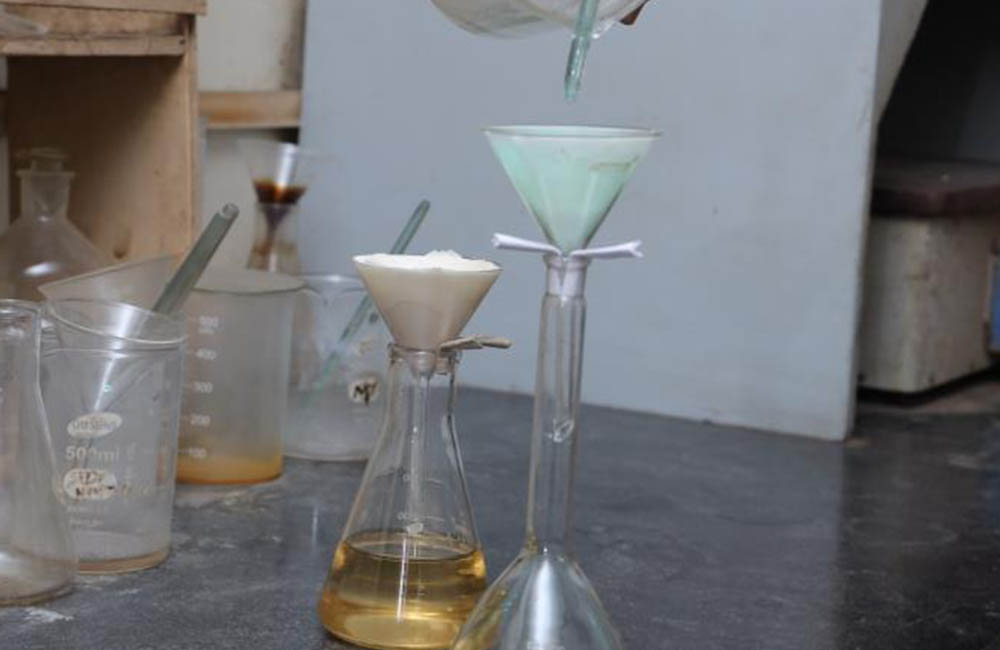

Chemical (Wet) analysis laboratory

-

Sand Testing Laboratory

-

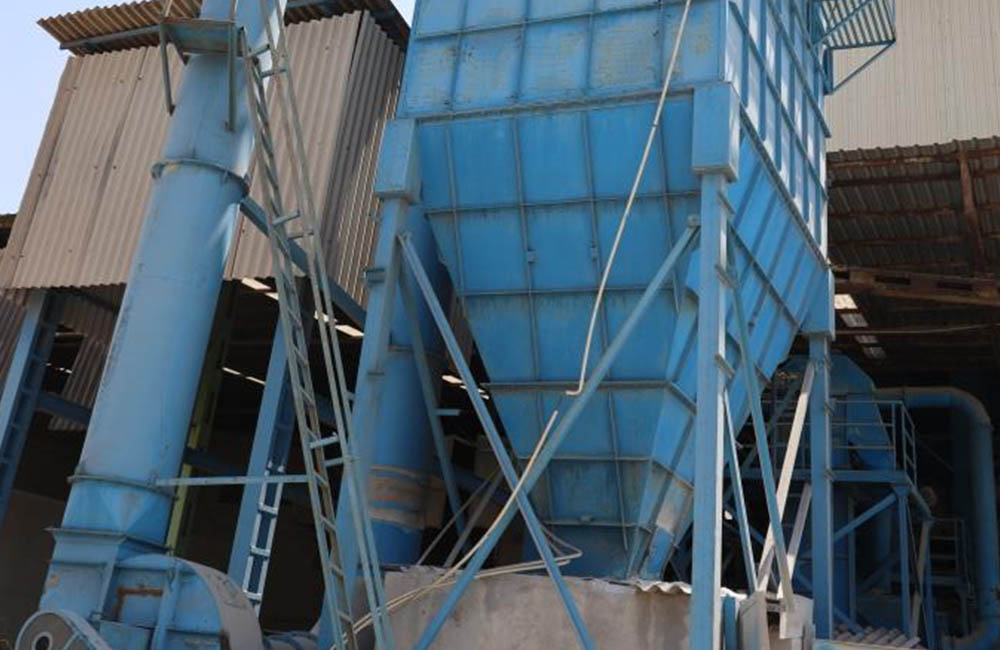

Sand Reclamation Plant of Wesman

-

Mechanical Testing Laboratory: Ys, Ts, % of elongation, reduction of area and Impact test @ room temp to -196°C).

-

Hardness Testing

-

Metallography Laboratory

-

Inter Granular Corrosion Test (IGCT) facility for practice A,B,E,C &

-

Dye (Liquid) penetrant test facilities.- ASNT Level II

-

Magnetic Particle testing- Dry and Wet method ASNT Level II

-

Radiography: Source-IR-192 & Co-60 isotopes.- ASNT Level II

-

Ultrasonic testing- ASNT Level I

-

RAD CHECK METER With External Detector, Type no. RC705B, Range Covered 0-10,000 µR/ hr

-

Fully equipped Machine Shop having CNC, VMC, HMC

-

Faro